Automotive, medical technology, white goods or consumer goods—in all markets, production requirements have continued to increase in recent years. Economic pressure and the highest quality demands require both a high degree of automation and sophisticated testing technology. Often, a multitude of trades and interfaces need to be coordinated: Automation technology, testing technology, quality data acquisition and evaluation, to name just a few.

Test engineering plays a key role here, as it is largely responsible for quality—and ultimately for customer satisfaction. The increased degree of integration and miniaturization of electronic products requires complex measurement technology, such that test bench projects often consist of a large number of sub-trades:

What would it be like to have a partner at your side who fully understands your requirements and can offer you an individual concept from a single source? With the AT Framework from Areus, this is exactly what we can offer you.

Our qualified team understands your testing and measurement task and develops exactly the right solution for you. This begins with determining your requirements. Together with you, we develop the right testing concept for your individual needs.

The Areus Test Framework (AT Framework) provides you with a comprehensive set of tried and tested software modules. In addition to the connection of a wide variety of testing and measurement devices, interfaces to quality management systems and databases are also available. Within a very short time, complex and professional testing and measurement tasks can be implemented efficiently and cost-effectively according to the modular principle.

This is complemented by the development of test stand-specific electronic hardware, e.g. signal conditioning or communication modules, as well as the design of mechanical components such as test specimen contacts and cable sets. Coordination by our experienced project managers guarantees that everything runs smoothly.

Sit back and relax when it comes to testing and measurement technology—Areus will take care of it! Our qualified personnel in production and assembly manufacture your test stands with the highest precision and quality. Comprehensive documentation and statistical measurement capability verification (MSA), calibration and self-diagnosis concepts are a matter of course for us. Our service team is always at your disposal for setup and commissioning in your production facility. We’re also available to you for maintenance and servicing in the tough day-to-day production environment. Areus testing and measurement technology with AT Framework: Test stands for the highest demands, made in Herrenberg.

The scripting capability of the AT-Framework ensures a clean separation between test sequence and hardware interfaces. Performance-critical software parts are programmed, qualified and tested in C# to ensure stability and safety. The test scripts can be modified by the user on demand, which allows fast and simple adaptations to changed requirements. Customized user interfaces, matching your corporate design, provide a uniform appearance that is familiar to the worker. You also benefit from continuously extended functions and modules.

In-system programming allows components and assemblies to be flashed during the function test. We implement in-system programming for our customers in existing and new procedures and test schedules. Areus’ procedures, which are customized to your needs, save you both time and money.

In addition to on-board solutions, external programming devices or special hardware can also be implemented.

We can offer you:

The software modules are:

In terms of hardware, the following modules are available:

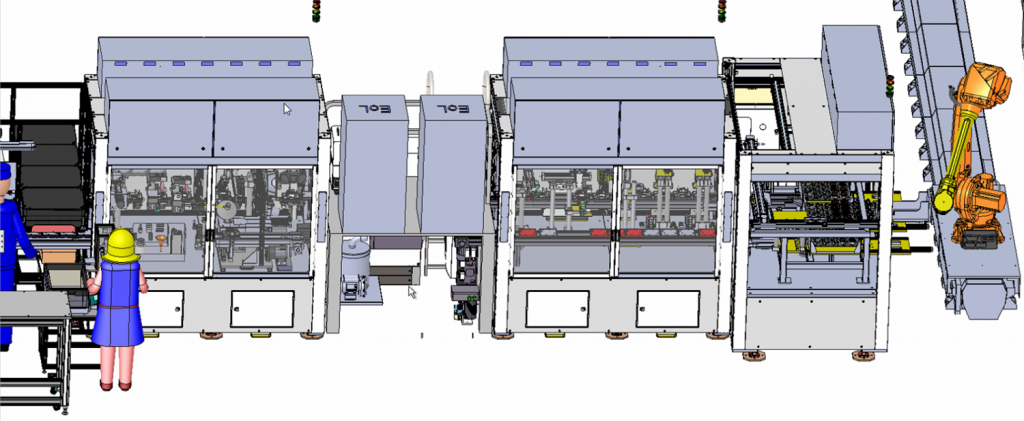

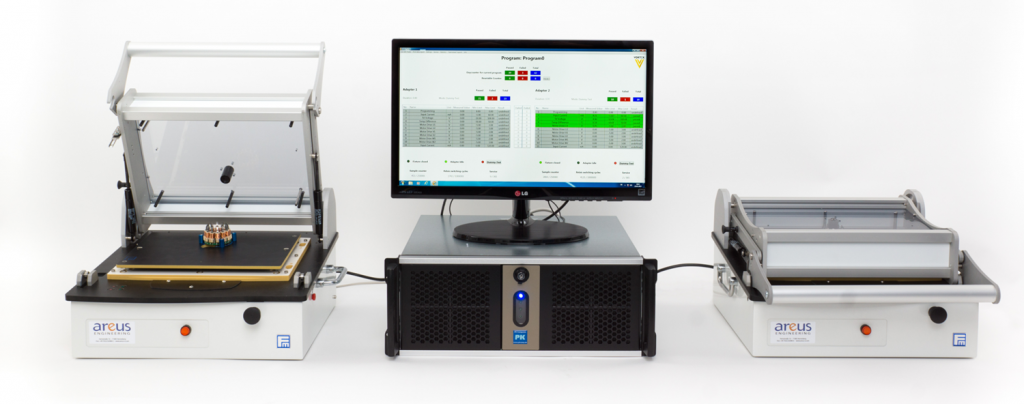

End-of-line test on three production lines according to IATF 16949 standard. Fully automatic testing with 3 test types, 60 DUT variants and integrated quality monitoring system.

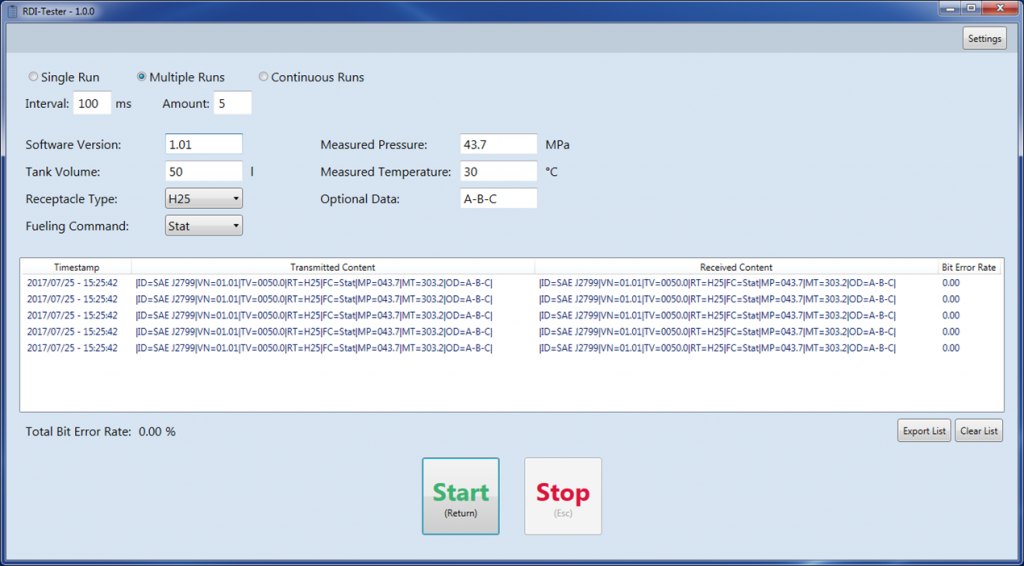

For an OEM: Test bench for quality assurance of the RDI ring in harsh external conditions such as humidity, extreme temperatures, dust and chemicals. Fulfillment of the SEA-J2799 / SAE-J2601 standards.

Test bench for CD ROM drives for vehicles that perform function tests in different conditions. Integrated climatic chamber and customized DUT adapter and cable set. Easy to use operating software and extensive documentation.

Component test bench with automatic labeling function and extensive statistics module

End-of-line test bench for final acceptance of multifunctional displays. Performance of electronic tests, communication tests, assembly tests as well as embedded function for flashing the firmware. The test bench has a self-test and diagnostic function as well as an ESD-compliant design. The labeling function allows good and bad parts to be separated from each other and the production batches to be tracked.